API6D, Testing Procedure & Double Block & Bleed versus Double Isolation & Bleed

September 13th, 2017 by Amanda Schumann

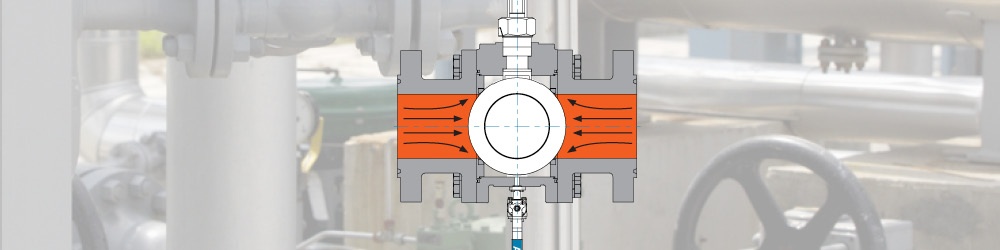

The API6D test for a factory tested ball valve in regard to seat leakage only requires seat leakage to pass test on the second seat on the other end of the valve in both directions. There is not a mandatory double block and bleed cavity drain test requirement unless especially requested by the customer. Consequently, many stockists when supplying a double block and bleed trunnion mounted ball valve simply fit a needle valve or a drain valve. You are required to specifically test the valve to make sure it has double block and bleed (DB&B) integrity (in the cavity between the 2 seats) to ensure the valve is holding pressure on the first seat. Note, I am referring to single ball DB&B, not double ball. The next point to be wary of is the API6D test procedure titled “double block and bleed” requires the valve to be tested from 2 sides at once whereas the “double isolation and bleed test” (DIB), would only require the cavity of the valve between the seats to be tested from both sides one at a time. Single piston effect seat (SPE) (which are most common) that are being used for DB&B service need to be tested as per API6D, DB&B test. Whereas double piston effect seats (DPE) only need to be tested as per the DIB test.

Of course double (twin) trunnion true “Double Block & Bleed” Ball Valves are superior, see our articles on these valves: –

DOUBLE BLOCK AND BLEED (TWIN) BALL, PLUG AND TRIPLE OFFSET BUTTERFLY VALVES

Also see these articles: –

FLOATING BALL WITH DOUBLE BLOCK & BLEED CAPABILITY

Check out this info from Valve-World on DBB vs DIB

Click here for more information on DB&B versus DIB and SPE versus DPE, etc.