Self Relieving vs Double Piston Effect Seals on Ball Valves

December 20th, 2017 by Amanda Schumann

API6D trunnion mounted ball valves with single piston effect seats (SPE) are designed to automatically release cavity over-pressure into the pipeline automatically using “self relieving seats”. Since body cavity and pipeline are isolated in the fully open and fully closed position, pressure trapped in the body cavity may be different than pressure in the line. Examples of this situation are during pipeline de-pressurisation, or temperature change of body cavity causing a sudden pressure build-up.

Over-pressure in the body cavity will pop the seats off the ball surface, and excess pressure will be relieved into the pipeline. After the pop-off action, the seats will return to their normal position, in contact with the ball.

The pop-off action is triggered by differential pressure between body cavity and pipeline. The body cavity pressure should not exceed in 1.33 times the valve pressure rating at the specified maximum operating temperature; however, pop-off action usually happens long before, with just a few bars of differential pressure. For standard API6D ball valves, both seats are self relieving. However, on request valves can be ordered with just upstream or just downstream seat as self relieving. Also “double piston effect” (DPE) seats can be specified. DPE seated valves must have an external relief safety valve fitted to the body which vents to atmosphere. Due to environmental requirements this must now be plumbed back into the upstream side of the valve or recycled elsewhere.

With SPE design, both seats are self relieving hence over-pressure can be relieved up or/and downstream. Custom ‘single piston’ (SPE) seats can be specified on one side, and ‘double piston’ seats on the other side to allow pressure to only automatically relieve just upstream or just downstream.

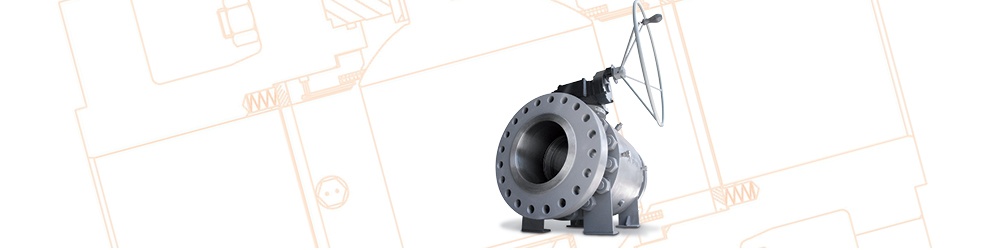

APV BVF100 Series

Ball Valve Seat Design Features – Self Relieving Seats vs Double Piston Effect Seats

Piston-Action Seats

As line pressure increases the seat reacts to the force of the pressure to form an effective seal. In the absence of line pressure, coil springs behind the seat provide a tight seal by keeping the seat in contact with the ball surface. Independent floating spring loaded seats are always in contact with the ball to provide an effective tight seal even at low differential pressure. Independent upstream and downstream seats permit draining of fluid from the body cavity, so allowing double block and bleed operation (closed position only). With the optional single sealing feature, there is automatic body cavity release of over pressure to the line through the down stream seat.

Self relieving seats (standard)

In self relieving condition, excessive internal body pressure is automatically relieved both upstream and downstream into the line by excessive pressure forcing the seats away from the ball.

Double piston effect (DPE) seats

With the ‘DPE’ seat option, if a leakage occurs in the upstream seat, the pressure entering the body cavity pushes the downstream seat against the ball and valve seals. Line pressure forces a seal against the floating seat.

An external body relief valve is installed to protect the body cavity from excess pressure which can be vented to atmosphere or recycled back to the upstream side of the valve or to flare.