API6A ANSI SCHEDULE Weld Neck Flange Slide Rule

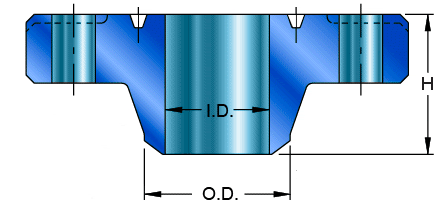

| Flange Size/Rating | Weld Neck Dimensions (Inches) | Flange-Material and Yield | Matching ANSI pipe size, schedule & yield PSI (K) | ||

|---|---|---|---|---|---|

| OD | ID | H | |||

| 1 13/16in 10M | 2.56 | 1.813 | 4.13 | Low Alloy 60K | Custom Pipe/Tubing 60K |

| *Indicates a heavier schedule pipe may be required - check pipe CWP with your pipe supplier. Items shown with asterix indicates a higher schedule could be required as follows:- | |||

| *1 Sched 80 | *2 Sched 100 | *3 Sched 120 | *4 Sched 140 |

| *5 Sched 160 | *6 Sched XXS | *7 Custom Pipe | |

’Obsolete’, ’discontinued’ or ’withdrawn’ API flanges have not been included in the above slide rule.

Important note:- the above slide rule assumes ambient temperatures. Additionally, as temperatures rise, the cold working pressure (CWP) rating reduces. Consult API and ASME pressure/temperature charts.

API Spec 6A does not specify overall height of 6BX weld neck flanges, only dimensions of each section of the flange. There are also allowable inbuilt tolerances and the bevel height is undefined. Consequently, the above height for API6BX Flanges is an approximate dimension only.

Weld Neck Flange Bores

API6A weld neck flanges has restricted bores to match standard ANSI/ASME pipe sizes and schedules. API Spec 6A specifies 45K yield strength material for 6A weld neck flanges (2,000 to 5,000 psi) with standard (restricted bore) weld necks. The smaller bore lowers the flange stress and allows the use of more easily welded material. API5L/ASTM carbon steel line pipe is lower yield then API6A flanges therefore a heavier wall is required. API6A weld neck flanges should have a matching metallurgical chemical composition to suit A106/ASTM pipe. In API6A 2,000 to 5,000 psi GSL stocks 45K rated weld neck flanges in carbon steel that are compatible with A106B/API5L ASTM pipe. In blind and companion 2,000 to 5,000 psi we stock low alloy steel 60K flanges. We also stock 10,000 psi API6BX blind and weld neck flanges in 4130 (or 410 stainless) grade in 60K and 75K. 10,000 and 15,000 psi API6BX flanges are typically manufactured in low alloy steel 4130 or 4140 (or 410 SS) hence higher grade compatible pipe is required. API Spec 6A does not provide specifications for weld neck Flanges in sizes above 11”. The above chart shows unofficial 6A weld neck flange dimensions in some common sizes over 11” as some operators require these flanges.

All API6A Weld Necks shown in the above slide rule in many cases exceeds API bore (I.D.) requirements. Oversized neck full bore API6A 4130 weld neck flanges are available on an indent basis. Oversized neck weld neck flanges have a larger weld neck O.D. to match API6A full port ‘integral’ flanged valves, spools or tubular products. Even though they are weld neck, once the full bore 6A flange is welded to a spool the flanges are deemed ‘integral’. The necks on these ‘Loose’ full bore API6A flanges do not usually match any pipe schedules. Another alternative is oversized neck flanges that mate with the next available larger linepipe size up.

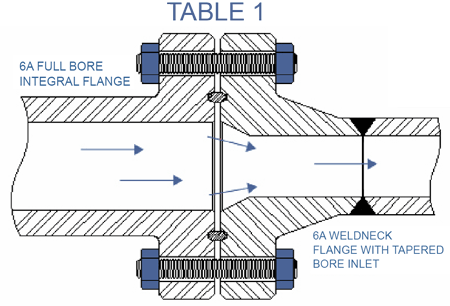

If mating a restricted bore weld neck API6A weld neck flange to a full bore integral flange, Global Supply Line Engineering can counter bore the restricted bore API6A flange to match a full bore API6A flange (see illustration table 1 below). API Spec 6A restricted bore weld neck flanges present problems when connected to full bore equipment due to a mismatching restrictive shoulder where the ‘full bore’ flange meets the restricted bore flange. Turbulence upon contacting this shoulder, may result in erosion which can cause premature failure of equipment. To prevent erosion problems 6A weld neck flanges may have a special entrance opening bevel as shown below in table 1. Alternatively of course, Global Supply Line can order full bore weld necks with over size neck. API6A does not specify full bore 45K weld neck flanges, so manufacturers must utilise 60K yield strength material for these flanges as they would for full bore integral flanges. Users who specify special weld necks that match standard pipe sizes on 6BX 10,000 & 15,000 psi flanges do so at high risk unless they include engineering and welding considerations in their decision process.

Compatibility of Weld Neck Flanges

In the above slide rule, the required schedule recommended of equivalent seamless carbon steel line pipe is based on the minimum yield shown (example 35,000 psi (35K) yield strength). The cold working pressure (CWP) of seamless carbon steel line pipe can vary between various grades and standards (and can be interrupted differently). Typically ANSI B31.1 and B31.3 line pipe is most commonly available in ASTM A106-B, API5LB and STM A53. Cold working pressures vary and standards are continually being changed hence the above table is only to be used as a guide.

Only use seamless line pipe 35K yield or greater, and use a wall thickness rated to the CWP of the API flange. Never use carbon steel line pipe with 10,000 psi flanges regardless of the schedule or rating.

Upon examining the CWP of API5LB/A106-B line pipe, the optimum wall size has been shown in he above slide rule. However users should check the CWP of pipe purchased, the above table is only a guide. Utilising high yield API5LX52 line pipe and F52 buttweld fittings will allow a lighter wall thickness and therefore a larger bore. F52 and X52 can be ordered to dual conform to 45K API6A.

The above slide rule shows the equivalent ASTM ‘normal bore’ size. ASTM – ANSI pipe sizes are based on a ‘nominal bore’ where as API6A sizes are based on the full port through bore size. However, you will see in our other API slide rule, equivalent ANSI sizes to mate with API sizes. Whilst in many sizes the flanging is the same, the rating of ANSI/ASTM flanges and pipe is lower, hence this slide rule shows possible schedule interrelations that ensure API6A cold working pressure ratings are not compromised. API and ASTM/ANSI pipe sizes also share common O.D’s in many sizes. The reason for this is that ANSI and API standards share a common ancestry. API6A now being the upstream standard has of course since increased pressures and ratings but the lower the old API ‘series’ ratings are now known as AMSI/ASME ‘class’ and have continued to be used down stream for applications which now fall under ASME/ANSI/ASTM standards.

Mating API6A 45K Weld Neck Flanges to Pipe & Fittings

As ASTM seamless line pipe is readily available and low cost, Global Supply Line stocks API6A 45K weld neck flanges in heavy schedules enabling GSL Engineering Division to machine weld necks to match required pipe schedule. This is an ideal solution for applications other than the main wellhead where full API port is not required. Furthermore, for the same reasons, carbon steel A234 WPB buttweld tees, elbows and reducers can then also be used which are readily available in the same welding compatible material as 45K flanges. The pressure rating of the schedule of fitting selected should match the rating of the API flange. These fittings are also stocked by Global Supply line in the same range of schedules.

The API6A 45K weld neck 3,000 and 5,000 psi PSL1 and PSL2 flanges Global Supply Line stock are to NACE MR-01-75 as it applies to down stream line pipe and refinery requirements. This does not allow a high level of H2S as may be specified for higher rated wellhead components which are rated to a higher level of ‘H2S’ service. Unlike API6A full port flanges they are not manufactured from 4140 or 4130. Ease of weldability is ensured as these 45K flanges are dual conforming to the carbon steel chemical composition of mating ASME/ANSI piping components such as A105N/A106B/A234 WPB etc. API6BX 10,000 psi 4130 flanges are only stocked in 75K yield in Blind and Companion (‘DD’, PSL2, NACE) and 60K yield in weldneck (‘DD’, PSL2, NACE).

Beware, some suppliers and manufacturers supply normal A105N 36K material flanges stamped as 3,000 or 5,000, these interconnect with API sizes (example a 2” ANSI A105 1500 class flange rated at 3,700 psi CWP is the same as a 2” 5,000 API psi CWP flange) but as A105 flanges are only 36,000 psi yield they are not rated to API cold working pressures.

Hammer Unions & Swivels in compatible materials

Global Supply Line also stock hammer unions in 4130 and 4140. However, for ease of welding we also stock buttweld hammer unions with forged A105N carbon steel welding ends up to 6,000 psi in 2” and up to 2,000 psi 4” to 8”. A105N is an equivalent, compatible grade of carbon steel to ANSI carbon steel line pipe, fittings and flanges mentioned above. One again the schedule of line pipe used must be rated to equal or greater cold working pressure than the union.

Information at this website is only to be used as a general guide and we do not guarantee it’s correctness. This information should not be used for any operational or engineering decision and Global Supply Line is not liable in any way. Anyone using information at this website does so at their own risk and assumes all liability.