Beginner’s traps painting ball valves

February 27th, 2017 by Amanda Schumann

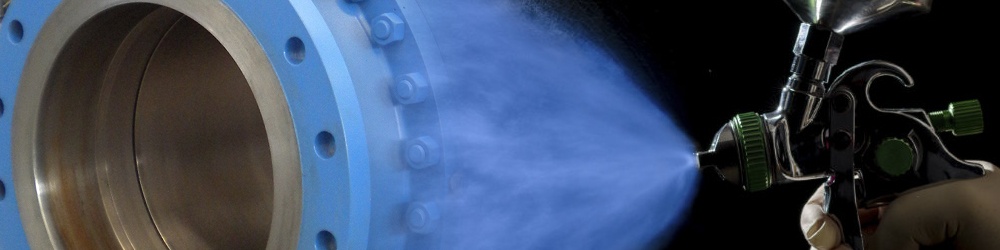

Even if you’re ordering from a quality valve manufacturer, they often sub contract out special painting of the valves. Typical problems involve not taping up the stem area or indeed the bore area properly or the tape falling off. Sandblasting residue can ingress into the stem area or into the seat area. Initially this may not be a problem but over time as the valve is opened and closed it can damage the stem seal area or cause extra friction and prevent the valve from opening or closing properly. Paint can also block the sealant fittings. For these reasons our Global Supply Line Engineering 9001 Lloyds facility performs all taping. Indeed our new facility has a fully quality controlled paint shop as there are many other traps in the area of painting from preparation through to final curing. Sub-contract painters often do things or don’t allow for things that affect the painting process such as using additional drying agents, humidity, base preparation, cleanliness, temperature, thickness, brand of paint, etc. Then there is the adhesion issue of over painting galvanised or zinc plated bolts, and so the list goes on. Sometimes the simplest part of the process can cause problems for the entire valve. Low temperature or high temperature valves also need a special paint grade. Heat numbers can become impossible to read so numerous issues need to be addressed.