Posts Tagged ‘valves’

The American Petroleum Institute API 6D Standard – Double-Block-and-Bleed Ball Valves

May 21st, 2024 by Amanda Schumann

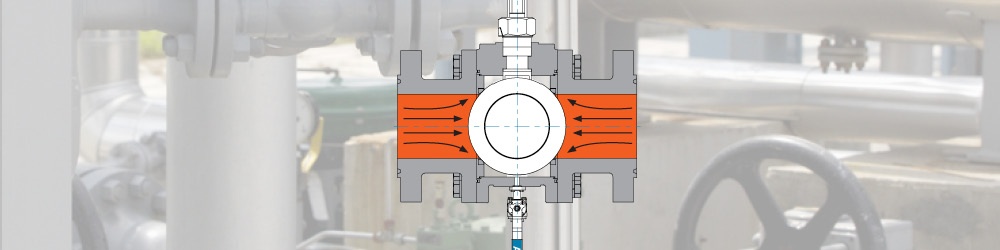

API 6D details three double block categories: DBB (double-block-and-bleed), DIB-1 (Double-isolation-and-bleed type 1), and DIB-2 (Double-isolation-and-bleed type 2). Trunnion Mounted Ball Valve Seat Designs Trunnion mounted API 6D ball valves have 2 seats that (one upstream, one downstream) can have a single (SPE) or double piston effect (DPE) seats. Single Piston Effect (PSE) Spring loaded […]

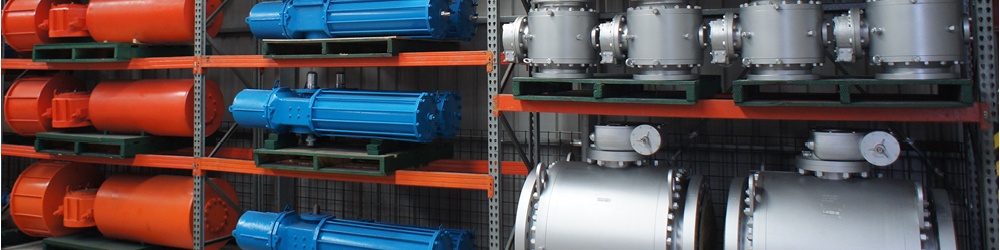

Global Supply Line is the largest Emerson Pneumatic Actuator stockist in the Southern hemisphere

December 4th, 2023 by Amanda Schumann

We are an Emerson approved distributor and the Australian Valve Centre valve engineering, test & automation facility is Emerson approved. We stock Bettis & Biffi double acting & spring return actuators up to 30,000 NB as well as accessories such as handwheel & gear over-rides. All automation & controls are performed in-house in our valve […]

Now also stocking

October 26th, 2018 by Amanda Schumann

Stock holding highlight on Vertical Shaft Drive Worm Gearboxes for Valves

Severe Service & Dirty Service

October 10th, 2018 by Amanda Schumann

Information on severe service and dirty service on quarter turn ball valves

Valve RFQ’s from overseas “Valve Dealers”

October 4th, 2018 by Amanda Schumann

Information about overseas valve dealers

Product Highlight – APV-BVF100-QF Trunnion Ball Valve

August 9th, 2018 by Amanda Schumann

Product highlight on APV BVF100-QF Trunnion Ball Valves

Improve Total Cost of ownership with valves

June 19th, 2018 by Amanda Schumann

Information on how to improve the total cost of ownership with valves

A CONTENTIOUS ISSUE

May 2nd, 2018 by Amanda Schumann

Information regarding Sealant Injection facilities on Trunnion Mounted Ball Valves

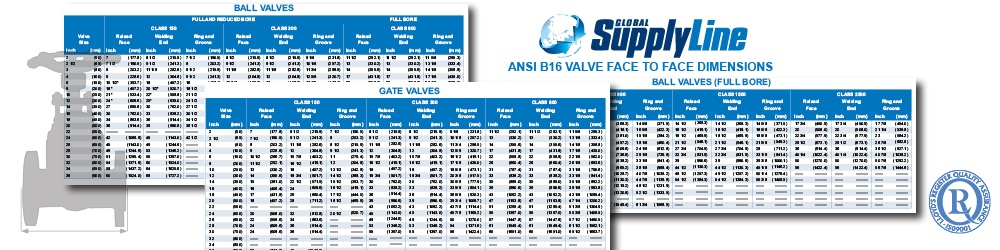

ANSI B16 Valve Face to Face Dimensions

April 12th, 2018 by Amanda Schumann

A technical guide on ANSI B16 Valve face to face dimensions

SPOTLIGHT – BACK SEATING ON API600 WEDGE GATE VALVES

March 14th, 2018 by Amanda Schumann

Product highlight on the back seating of API 600 Wedge Gate Valves

Proven design, superior quality, price and delivery

March 7th, 2018 by Amanda Schumann

Technical and Stock range information about CVS products

VALVE SOLUTIONS FOR OIL & GAS, MINING AND PROCESS INDUSTRIES

November 29th, 2017 by Amanda Schumann

METAL TO METAL SEAT BALL & PLUG VALVES Global Supply Line supply flanged, weld and screwed end severe and critical service valves manufactured by Starline, Sferova, Energy Valves and Australian Pipeline Valve. Also available, true full bore top entry plug valves for slurry and dirty service. BUTTERFLY VALVES 100{25ff19fb4bbe50b2512a26092ffa8499fbe25baf0e752d653cb6adacb3479290} Shut-off, true metal to metal seat […]

COST REDUCTION & EFFICIENCY IMPROVEMENT STRATEGIES

November 22nd, 2017 by Amanda Schumann

SINGLE SOURCE SUPPLY Single source procurement patterns are now becoming increasingly popular. GSL has strong long term alliances with various manufacturers and suppliers giving us a high level of capability to manage single source supply agreements. We can quote on fixed term contracts/blanket orders to supply valves, flanges, fittings and all pipeline components and manage […]

API6D, Testing Procedure & Double Block & Bleed versus Double Isolation & Bleed

September 13th, 2017 by Amanda Schumann

The API6D test for a factory tested ball valve in regard to seat leakage only requires seat leakage to pass test on the second seat on the other end of the valve in both directions. There is not a mandatory double block and bleed cavity drain test requirement unless especially requested by the customer. Consequently, […]

Spring Return Deadman Handle for Quarter Turn Valves – ex stock!

August 16th, 2017 by Amanda Schumann

Spring Return Handle provides unassisted opening or closing of manually operated quarter turn valves. The model 71 and S7 Spring Return Handle for example, driven by a powerful, completely enclosed torsion spring, automatically returns the valve to the desired fully-open or fully-closed position when released. Automatic valve repositioning is a convenience and safety feature for […]

Large Trunnion Ball Valve History

July 13th, 2017 by Amanda Schumann

Early last century there was Cameron (USA) (which the Russian’s copied!) and then WKM (USA), then along came Grove (USA), in Japan along came Kitz, then KTM and IKS (WKM under license). In Europe there was Borsig (Germany) and TK (Scotland), not long after in the early 70’s came BC Richards Australia (who also made […]

Stock Holding Quality Points of Difference

June 7th, 2017 by Amanda Schumann

Examples of our stock holding quality points of difference include: – Anti corrosive film on internals and gasket face Selected stainless and zinc plated top works components. Stainless external components such as sealant injection nipples on premium brand ball valves. Equilibrated 2-stage disc on large size globe valves as well as hammer blow hand wheels. […]

Valve Selection Criteria

May 4th, 2017 by Amanda Schumann

You’ll find these handy tables and many more in the Valve Technical Library at our website. Click here to view and bookmark all of our valve and piping technical references.

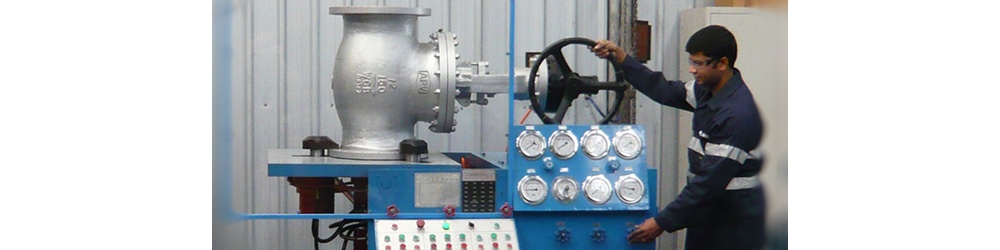

API 598 Testing – Optional Seat Test

April 5th, 2017 by Amanda Schumann

Seat testing optional, did you know? The table below shows API 598 testing is optional in several key test areas. Global Supply Line and Australian Pipeline Valve always perform all hydrostatic & pneumatic tests whether optional or not, whether from stock or indent. In addition, Global Supply Line also provide full certification on all trim […]

Tip of the day – Young player’s trap fitting actuators to trunnion mounted ball valve from stock

March 24th, 2017 by Amanda Schumann

Trunnion mounted ball valves often have corrosion inhibitor in the sealant injection lines to prevent corrosion during ocean transport or due to humidity etc. The trouble with this is, nowadays they use synthetic oils. Synthetic oils become dry and tacky, and the seat and ball area become dry and tacky/sticky. After the actuator is […]