Posts Tagged ‘testing’

VALVE TEST STANDARDS

February 1st, 2018 by Amanda Schumann

A Technical guide to valve test standards

Differencies between ISO 15848 and TA-Luft

September 6th, 2017 by Amanda Schumann

TA-Luft TA-Luft only deals with stem sealing area. Also, no third party witness is needed. The TA-Luft test qualifies only a “high-quality sealing system”. TA-Luft is considered to be complied with if metal bellows with a safety energised packing or similar sealing systems are used; as per VDI 2440. TA-Luft does not specify the number […]

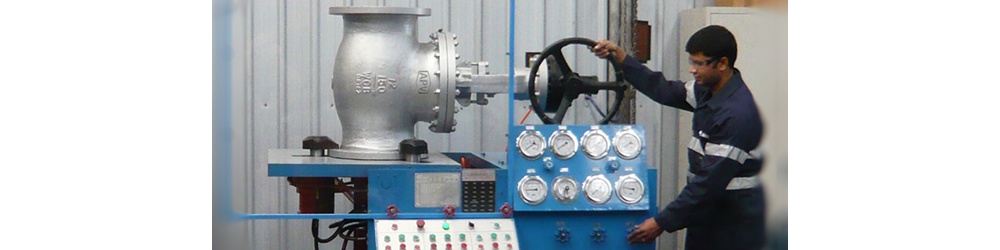

API 598 Testing – Optional Seat Test

April 5th, 2017 by Amanda Schumann

Seat testing optional, did you know? The table below shows API 598 testing is optional in several key test areas. Global Supply Line and Australian Pipeline Valve always perform all hydrostatic & pneumatic tests whether optional or not, whether from stock or indent. In addition, Global Supply Line also provide full certification on all trim […]

PMI Testing

October 4th, 2016 by Amanda Schumann

Global Supply Line offers positive material identification if required with no delay. We have in-house non destructive metallurgical testing capability for the following chemical elements: A105, WCB, LCB, LF2, LCC, WCC, CF8, CF8M, F51, F53, A20, Monel etc. Of course all product is supplied with factory 500493.1 certificate as standard, however should you require additional […]