Compact Quad Rack & Pinnion Actuator

February 14th, 2018 by Amanda Schumann

INTRODUCTION

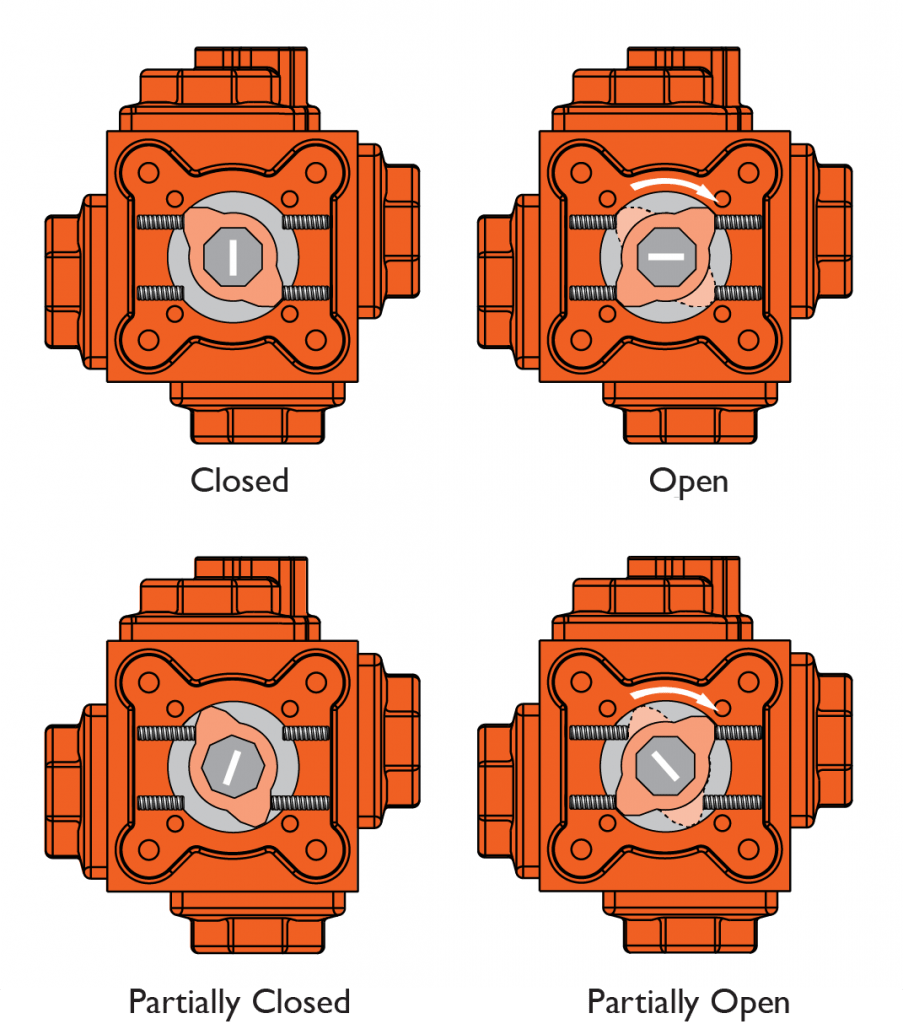

The ATZDF actuator is a quarter-turn rack & pinion pneumatic actuator that doubles the torque of standard pneumatic actuators. The superior performance is achieved by Torqturns four piston design, which generates torque around a centrally located piston. This produces double the power for the same size actuator or half the size for the same amount of torque.

The ATZDF has four small cylinders, one located on all four sides. The smaller pinion and shorter travel distance of the pistons in the ATZDF require less air pressure than a larger double piston actuator to produce the same torque output. This results in faster response times for emergency shutdown applications as well as lower air pressure for operation and reduced maintenance.

REDUCED SIZE

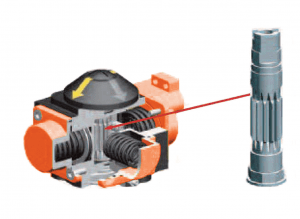

The Torqturn Pneumatic Actuator Series 4×4 supplies more than double the torque of conventional rack and pinion actuators. That’s because it has four pistons generating torque around a centrally located pinion. With more pistons in the actuator, it allows their diameter to be smaller while generating higher torque. At the same time, it means the size of the actuator can be more compact, reducing weight and avoiding stem wear that may be caused by imperfect mounting. With four small cylinders each located on one of four sides of the unit and at a given air pressure, the 4×4 produces the same torque output as double piston models using smaller diameter pistons and a narrower pinion. Thanks to the narrower pinion, the pistons travel shorter distances so that they can move faster from one position to the next.

REDUCED AIR CONSUMPTION

The cube shape coupled with pistons travelling shorter distances minimises size requirements while maximising torque output. At the same time, shorter piston travel and compact size greatly reduces pressure requirements compared to other designs and results in reduced energy expenditures.

MORE FLEXIBLE SOLUTION

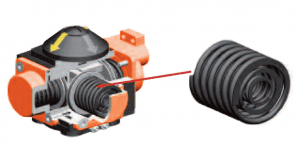

Because of the four-cylinder design, the 4×4 has many more spring combination possibilities than double piston actuators removing the need to compromise. This means better solutions under any air pressure requirement. Each chamber can use up to three different spring sizes which nest between the covers and pistons and align by centreing rings. Also, springs are wound in opposite directions to avoid tangles during operation.

STRONGER

For superior corrosion resistance, the body and covers are anodised internally and externally. In addition, they have an external epoxy base layer and a second polyurethane paint layer further reduces corrosion in demanding applications. Extended spray wash downs do not create corrosion problems for the actuator.

Travel stops can be adjusted by four studs at the base of the actuator. The studs are opposed from each other so no unequal forces are generated, the stop design allows for 1 -/+ 5º adjustment in both opening and closing rotations. Mid-stroke stop points can be achieved with longer studs.

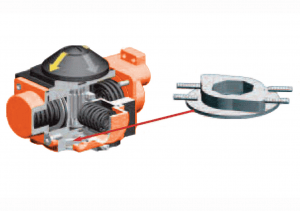

Blowout proof and Acetal support pad in body maintains proper contact of the piston racks to the pinion at all times.

Nested springs are aligned by rings cut in the piston face and end cap. This ensures correct orientation. With four cylinder areas, many different combinations are available allowing for correct sizing.