DOUBLE BLOCK AND BLEED VALVES – DUAL VALVE

February 28th, 2018 by Amanda Schumann

Double Ball/Plug DB&B valves

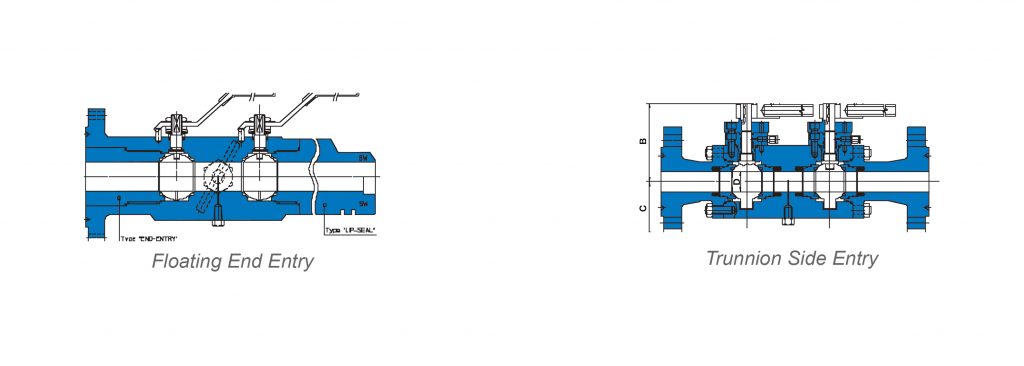

With the need for verifiable and maintainable shut off in safety critical applications, double block and bleed valves have commonly been used for primary and secondary tight shut off, in an attempt to provide and ensure system integrity. Historically, system integrity would be achieved through the use of two individual isolation valves, a spool piece and a bleed valve that had the disadvantages of extensive cost and weight and also increased the risk of emissions due to multiple flanged faces. Consequently, combined integral DB&B valves are now widely used. These valves have a single or side entry body design with dual Ball or Plug valves with a bleed valve installed between the two main line valves. These valves are available bi-directional in metal seated and soft seated style, in bubble tight shut off. Sometimes called twin valves, DB&B valves are available in Plug and Trunnion Ball type up to 600mm NB in ANSI 150 to 2500 class. These DB&B design valves replace existing traditional techniques employed by pipeline engineers to generate a double block and bleed configuration in the pipeline. There are several designs and configurations of Double Block & Bleed valves as follows:-

Single Ball Trunnion DB&B

Single Ball Trunnion DB&B

Conventional single ball trunnion mounted ball valves have two energised generally bidirectional seats. The body cavity can then be fitted with a drain valve at the body cavity drain point to allow verification of seat integrity and this type of valve is then sold as a “Double Block and Bleed Valve” (DBB). Australian Pipeline Valve individually tests each valve to verify zero leakage at the drain point. Conventional single ball trunnion valves typically feature self relieving ‘single sealing’ seats which automatically relieve body cavity pressure downstream. Uni-directional valves can be specified which only relieve upstream. Conventional single ball design still allows a closed valve to leak up or downstream should the body cavity over pressurise.

Double piston effect (DPE) seats can also be specified on single ball DB&B trunnion valves. This style of valve is classified under API6D as a “Double Isolation and Bleed valve”(DIB). This design ensures that both seats are always sealing, even if one seat does fail, the other seat will continue to maintain a seal as the two way seats maintain a bi-directional seal. With DPE seats, a body cavity external pressure relief valve is fitted (which can be optionally by-passed back to the upstream flange of the valve or to flare). This is a cheaper option than twin ball DB&B valves whilst still providing a high level of integrity.

For a full definition of API 6D double block & bleed vs double isolation & bleed click here.

Furthermore, we can even supply a floating ball ‘trunnion style’ design up to 200NB (8”) 600LB (APV model BV100-F26) with an energised double sealing seat system incorporating metal seat retainers. This design offers the advantages of DB&B DPE seat trunnion valves without the disadvantages of elastomers, bearings and extra seals that could cause valve failure. (Refer to the APV Special Service Ball Valves catalogue click here. For more information on Starline DPE seat trunnion valves, click here.

However, due to insurance reasons as well as for absolute sealing integrity, some customers require a dual ball or plug style to provide a higher level or assurance.

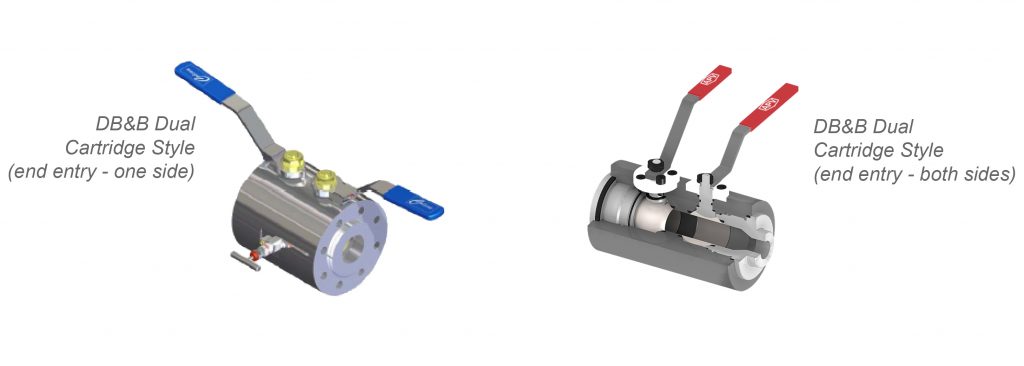

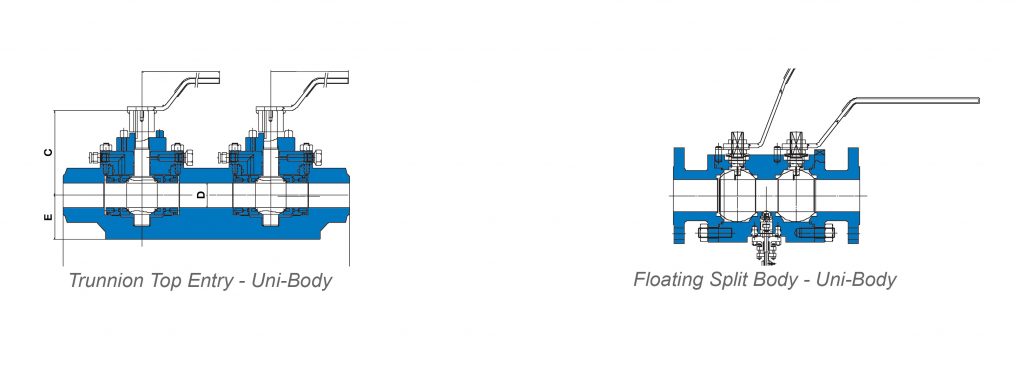

Cartridge Type Standard Length Dual Valve Trunnion & Floating DB&B Valves

Compact cartridge type standard length DB&B valves consist of two valves and a bleed valve in one (side entry) compact cartridge type unit with ANSI B16.5 flanged & tapped connections. This design configuration allows the same face to face dimensions as a single block ball as specified in API 6D and ANSI B16.10. (Several of Global Supply Line’s manufacturers can produce this type of DB&B ball valve in floating and trunnion configurations). In addition, an integral one piece body design is also available on top entry and end entry design (see drawings on last page) further eliminating potential leak points.

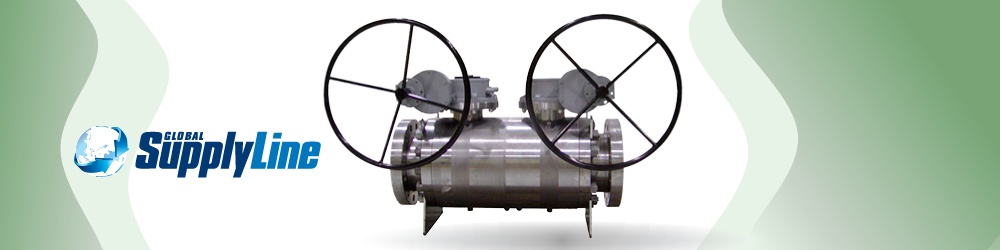

Fully Flanged Long Pattern Dual Valve Trunnion DB&B Valves

DB&B valves feature the traditional style of flange-by-flange type and is available with ANSI B16.5 flanges, hub connections and weld ends. Starline Srl, Sferova Srl and Australian Pipeline Valve who can all manufacture this type of DB&B Ball valve in all sizes and classes. We can also supply and integral uni-body top entry configuration that has no side body flanges.

Double Block & Bleed Plug Valves

Double Block & Bleed Plug Valves

Global Supply Line also represents Energy Valves who can manufacture DB&B Plug valves in lubricated and non lubricated types. Our manufacturers can supply pressure balanced style (also referred to as dynamic balanced) in rectangular port, inverted plug and full circular port.

Both these single body DB&B designs have operational advantages as there are less potential leak paths within the double block and bleed section of the valve.

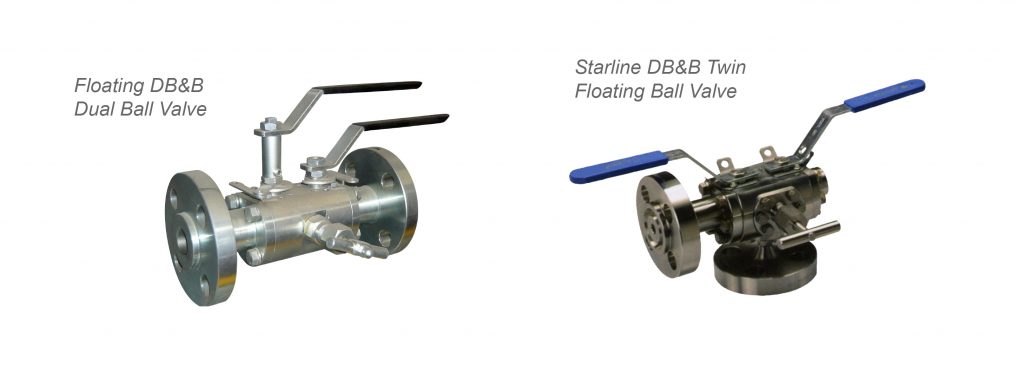

Dual Ball Floating Design DB&B Valves

In smaller sizes typically from 8NB (1/4”) to 150NB (6”) Floating Ball design firesafe certified Twin Ball Double Block & Bleed valves are also available. For more information click here. Global Supply Line can supply this style of valve in very short delivery in A105N, LF2, 316, F51, etc., in 150 to 2500 Class in as quick as 2 weeks depending on the configuration.

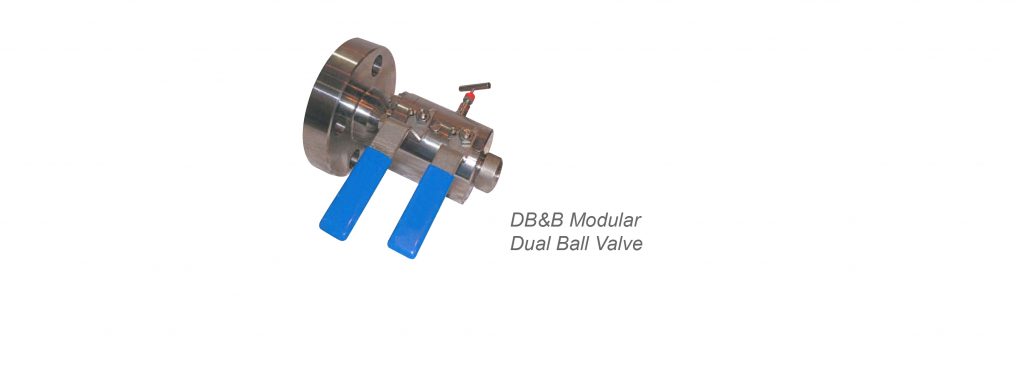

Lower cost firesafe certified modular DB&B Dual Floating Ball valves are also manufactured by Colson Industries and Australian Pipeline Valve in flanged & screwed ends. Global Supply Line are agents for Colson Industries, for more information click here. This style can also be configured with one ball plus one needle valve in-line with an additional needle valve side bleed in cartridge style configuration with tapped ends to suit flanged connections both ends. For instrumentation use, mono flange wafer style, needle valve type DB&B valves are also manufactured by our European manufacturers in as quick as 2 weeks depending on the configuration.

Single Cast Double Block & Bleed Triple Offset Butterfly Valve

With the weight and price advantages of zero leakage Triple Offset ‘metal to metal’ seated Butterfly Valves clear to be seen, this solution integrates these features into a one piece cast body. A primary advantage of this design is that it has an increased cavity between both discs, reducing the possibility of a breach during full pressurisation and further enhancing safety performance in critical applications. A wide range of sizes and pressure classes are available up to ASME 1500 class. This valve will replace a standard single ball trunnion ball valve as in most sizes it is the same face to face dimension.

For catalogues and information on our manufacturers of Double Block & Bleed Trunnion (twin) ball valves, for Starline click here, for Sferova click here, for Australian Pipeline Valve click here, and for Double Block & Bleed Dual Valve plug valves click here.

Global Supply Line can supply DB&B Valves in short delivery times world wide.