Korean Valve Firesafe Certificates – Questionable?!

March 15th, 2017 by Amanda Schumann

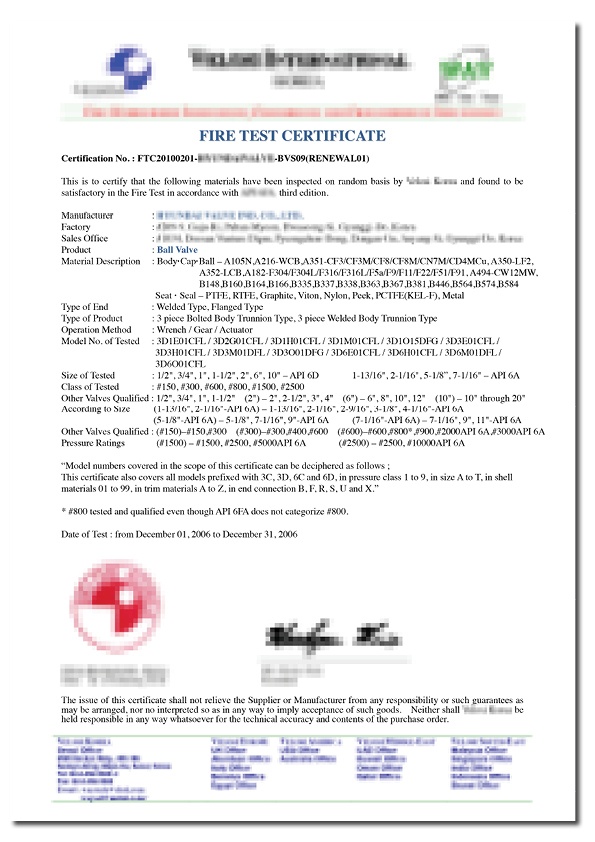

Most people would have noticed that companies in Korea use the same certificate/witness to produce all valve firesafe certificates.

Does anyone ever notice that these certificates have every single Class (150 to 2500), for each individual valve type, every single material grade (Duplex, Stainless, Carbon, Alloy, etc.), every size (1/2” to 60”) and every seat type under the sun? If you were to examine each individual model of valve in floating/trunnion, testing each style/design they would have to have tested up to 35 valves per model to truly have this range of coverage. You will notice (if drawing numbers are referenced) only a small number of drawing numbers is referenced which does not correspond to the number of valves covered above. Frequently one piece, two piece & three piece and even welded body, cast & forged valve models for a large range of classes are all listed on one certificate. The Shell approved European manufacturers don’t even have this range of coverage on their firesafe certificates. What I am told under good authority is that what the firesafe authority in Korea normally does is actually rent the factories the certificates really cheap but on a yearly basis so they have to keep paying to renew each year which is of course ridiculous as this a one off design test and once you’ve done it, you’ve done it, unless you change your design. In return for this, one would suspect that they are writing virtually anything they want on the certificate as it is impossible to believe that such small companies can have done such a wide range of valve testing over many models.

The above certificate is just an example of one size and one model. Taking into account floating and trunnion, flanged and screwed, cast and forged, each company would have to have typically 15 different models, multiply this by 35 valves, approx. $4k per valve, then it would cost $2 million and that assumes zero failures. API607 which is mirrored by ISO 10497 requires every second class and every second size of valve is tested in addition to this you have to test a mid range size valve in austenitic stainless to cover that range (again in every second class). Every model and body style forged & cast, trunnion & floating needs the full size & class range tested. Even then, only the range of seating tested is technically covered where is once again on the Korean certificate you will see they have every seat material under the sun covered. It would be more like 80 valves per model size not 35 if they really had done this. If you also factored this in and 30{25ff19fb4bbe50b2512a26092ffa8499fbe25baf0e752d653cb6adacb3479290} failure rate it would be over $6 million!! You’ll never see this much coverage on any other certificate because even big multi nationals would not test this many valves, it would just be ridiculous.

In reality of course many valves supplied by the huge multi-national valve manufacturers are not truly always firesafe certified if they have a different seat than the one they used to test the valve. It just comes back to trusting that the manufacturer understands the characteristics of his valve design to know that the firesafe design is still upheld with the different seats and seals.

In terms of China firesafe certificates, most don’t state model, seats, drawing number, floating or trunnion? 2 piece or 3 piece? forged or cast? etc. Also most do not show the full class, size and material range covered required by API607/ISO 10497.

Australian Pipeline Valve were one of the first manufacturers in the world to obtain API607 to the 5th Edition and now we are ahead of the rest with the majority of our valves having been tested to the latest 6th Edition ( and ISO 10497) AND our valves are also DNV Witnessed. Many in Asia do not get the valve test witnessed and of course without a credible witness money can be paid to get any test to pass. API6FA is now obsolete other than for gate valves. Once again Australian Pipeline Valve is one of the few manufacturers in the world that has DNV Witnessed, firesafe certification for gate valves. We’re also one of the few manufacturers in the world to have API607/ISO 10497 certification for pressure balanced lubricated plug valves as well as high performance double offset soft seated butterfly valves (some have it for metal seated but almost no one has it for soft seated). Very few lubricated plug valve manufacturers have any firesafe certification and even the ones that do only have the long obsolete BS 6755 firesafe test which were made obsolete over fifteen years ago and did not require any nominated ‘coverage range’.

In addition we have fugitive emission DNV Witness tests done on our entire range of quarter turn valves and gate valves.

Check your plant insurance as should a problem occur with a valve and you haven’t done due diligence on the firesafe certificates for the valves you are buying your insurance won’t cover you. Another major problem with many Asian firesafe certificates is the model number of the valve isn’t referenced so you don’t even know what model it is that they firesafe tested. Australian Pipeline Valve certificates are fully traceable in addition we have a DNV signed and stamped drawing available for all the tested valves.

When you deal with Global Supply Line you’re dealing with the company that on your behalf has checked the firesafe certificate credentials on all the manufacturers we deal with including JC, Sferova and Starline. In addition we have checked and loaded all their firesafe certificates at their section of our Global Supply Line website so when we quote you a valve you can click straight onto our website, with no password and view all the firesafe and fugitive emission certificates of the manufacturers we represent including Australian Pipeline Valve.