Mechanical Partial Stroke Testing Actreg-JC

November 6th, 2023 by Amanda Schumann

Click here to view more information on mechanical partial stroke testing.

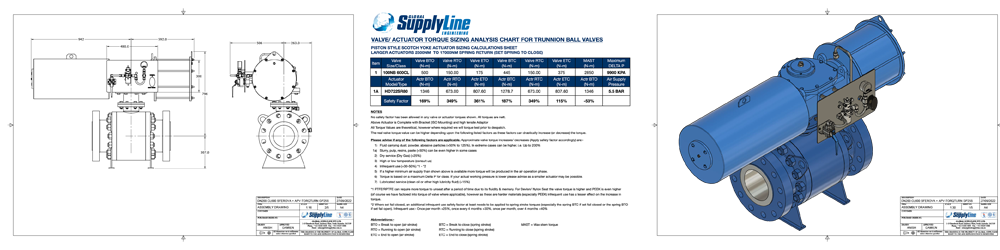

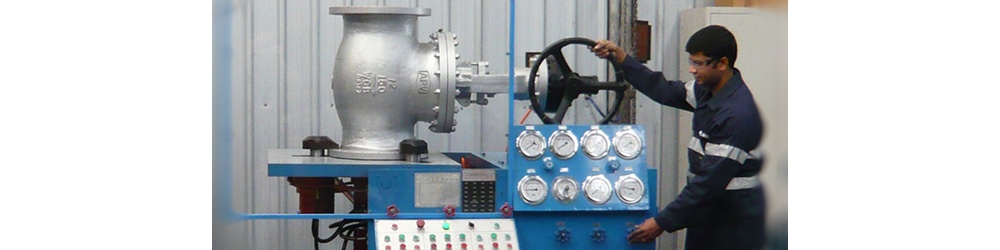

Complete Actuation Packages

February 21st, 2023 by Amanda Schumann

The Australian Valve Centre, Global Supply Line Engineering is a full Lloyd’s ISO 9001 certified facility. We have full in-house actuation, design, automation & test facilities. Everything is made in-house using all ex stock components including the valve, the actuator, all panel & control components.Complete actuation packages available are 3D model, torque testing, hydrostatic and […]

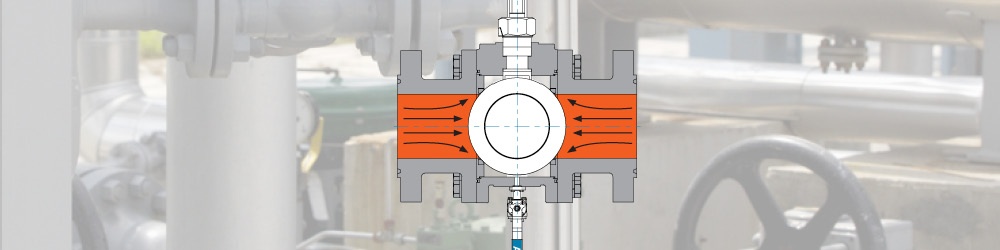

API6D, Testing Procedure & Double Block & Bleed versus Double Isolation & Bleed

September 13th, 2017 by Amanda Schumann

The API6D test for a factory tested ball valve in regard to seat leakage only requires seat leakage to pass test on the second seat on the other end of the valve in both directions. There is not a mandatory double block and bleed cavity drain test requirement unless especially requested by the customer. Consequently, […]

API 598 Testing – Optional Seat Test

April 5th, 2017 by Amanda Schumann

Seat testing optional, did you know? The table below shows API 598 testing is optional in several key test areas. Global Supply Line and Australian Pipeline Valve always perform all hydrostatic & pneumatic tests whether optional or not, whether from stock or indent. In addition, Global Supply Line also provide full certification on all trim […]

PMI Testing

October 4th, 2016 by Amanda Schumann

Global Supply Line offers positive material identification if required with no delay. We have in-house non destructive metallurgical testing capability for the following chemical elements: A105, WCB, LCB, LF2, LCC, WCC, CF8, CF8M, F51, F53, A20, Monel etc. Of course all product is supplied with factory 500493.1 certificate as standard, however should you require additional […]